concrete protection

LONGER SERVICE LIFE FOR CONCRETE BUILDINGS

This product group offers a complete, premium quality selection of plastic liners that provide perfect protection for concrete. The main focus here is on protecting concrete against environmental influences and aggressive or abrasive media, in order to improve the service life of concrete works.

Concrete protective liners are used wherever a concrete building faces tougher requirements. The main applications for concrete protective liners are, in particular, in transportation and storage of liquids, and where chemical resistance cannot be ignored.

Effective protection for concrete is ensured by the combination of the benefits of special thermoplastic liners (flexible, ductile, no corrosion) with those of concrete (high strength, high stiffness). The concrete is effectively protected thus prolonging the building’s service life. Concrete protective liners are thus usable in numerous concrete building applications, for example, in renovation. Absolute mechanical anchoring and bridging of cracks in concrete, as well as excellent shear and impact strength and the durability of the liners for concrete protection are just a few of the many benefits.

Concrete protective liners are welded together thus creating permanent and reliable joints. Depending on the project requirements, heated element butt welding, extrusion and hot wedge welding are necessary for a reliable and leak tight weld, which additionally offers chemical resistance.

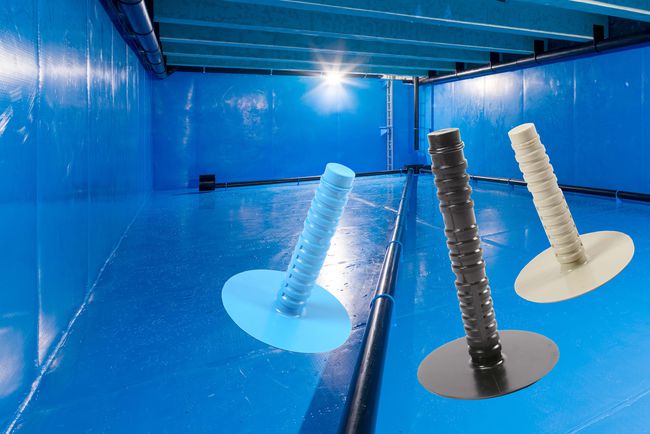

Concrete anchor injection molded

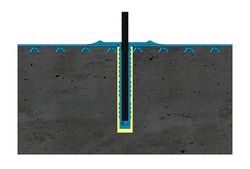

Accessories and Appurtenances (e.g. ladders, pipes, etc.) require proper mounting in concrete structures which are lined with concrete protective liner or HYDROclick.

The new AGRU concrete anchor was developed to guarantee a tight mechanical connection to the concrete structure. Previously this was often accomplisehd by unique customer solutions.

The concrete anchor and the lining system provide a 1oo% leak tight weld through extrusion welding as they are produced with the same thermplastic resins.

AGRU’s new concrete anchor provides flexibility in solutions by offering products in different materials, lengths and dimensions.

Supply Range Code 582

Dimensions | Material |

|---|---|

M16/200 mm | HDPE black / PE 80 blue / PP-R gray |

M16/150 mm | HDPE black / PE 80 blue |

M12/200 mm | HDPE black / PE 80 blue |

M12/150 mm | HDPE black / PE 80 blue / PP-R gray |

Benefits & Features

- available in multiple materials and dimensions

- 100 % leak tight solution due to welding compatiblity with the concrete protective liner and the HYDROclick system

- easy and fast installation

- integrated circumferential chamfer reduces welding preparation time